OxyFog

Our vision in open-sourcing this project is to help the scientific community work with inexpensive but capable plasma systems to develop new applications. We are happy to discuss your ideas and/or your contributions to this project. Please send an email to Dr. Greg Fridman at greg@aaplasma.com.

An open-source plasma oxidation chamber for research and education

The OxyFog system with a large chamber

Manual control unit

One of the two nebulizer fluid containers

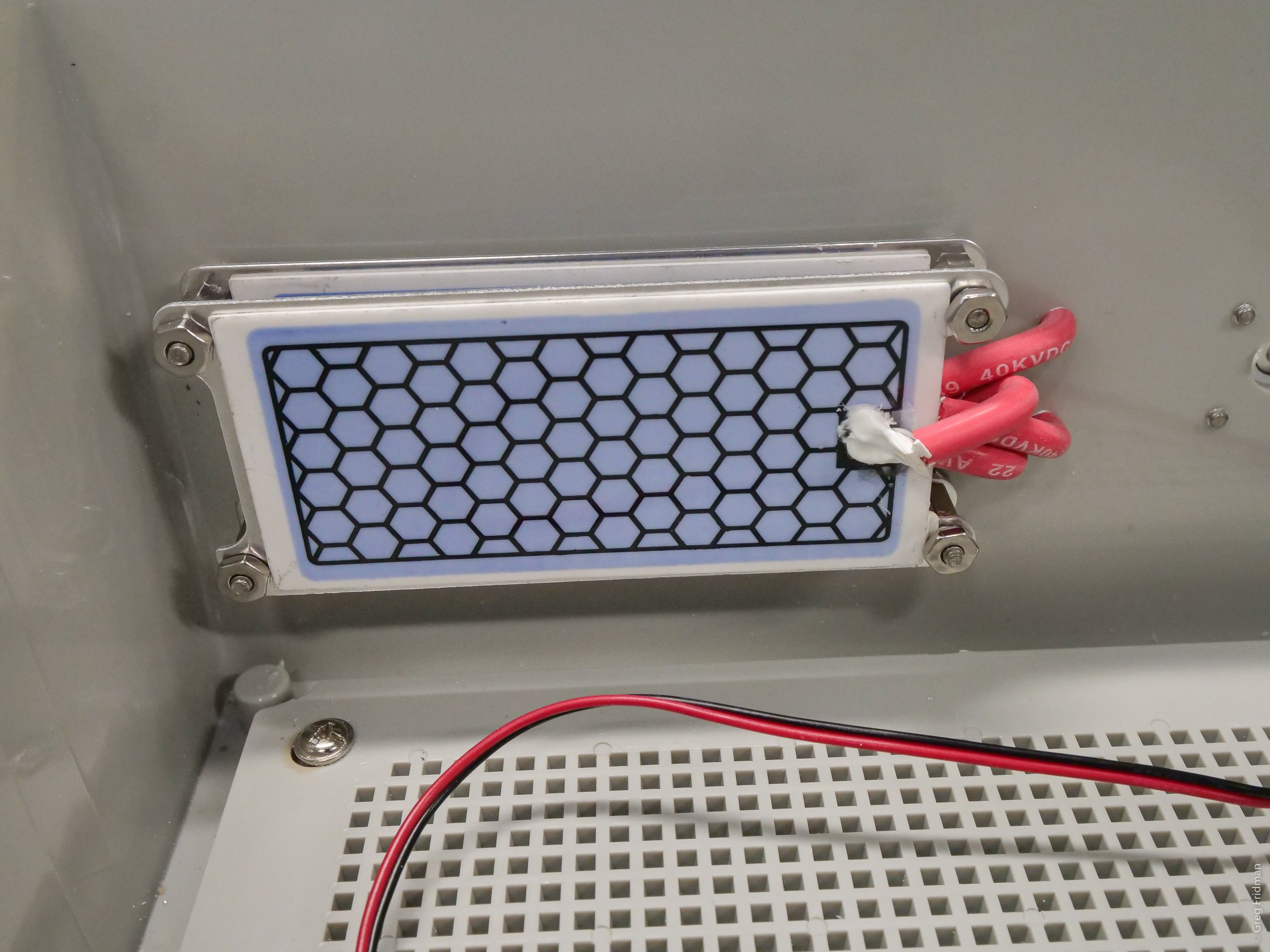

One of the two surface plasmas

Recirculation fan can be positioned anywhere in the chamber

The box has soft rubber lining and offers a good air-tight seal

Chamber with the heating coil

Water mist coming out of the nebulizer

Capabilities

OxyFog is a potent and capable plasma chamber with ultrasonic nebulizers to introduce liquid fog for mixing with plasma. Our system capabilities include:

Two fluid nebulizers

Two surface dielectric barrier discharge plasma generators

Fan for recirculation inside the chamber

Heating coil and fan to destructively-remove residual reactive species, produced in plasma

Independent controls for all the functions

Useful applications

This project was funded, in part, by NASA. We think that the list of potential applications for a high-humidity plasma system is endless, but here are some ideas:

Fresh produce decontamination

Aging of materials by exposing them to a highly corrosive environment

Decontamination of surgical equipment and tools

Decontamination of PPE equipment

Deposition of coatings at atmospheric pressure

Purchased parts list

Main chamber. While the size of the box is not essential, the one we have selected is 15.4″x11.4″x6.3″.

Polycase WH-10 enclosure is used for all the controls.

Dernord™ clamps and 38 mm glass chamber are used to house the heating element.

Two ultrasonic atomizers are used for fluid fogging.

Two 110V ozone generators are used as an inexpensive source of surface dielectric barrier discharge production.

The rest of the hardware (rocker switches, fans, screws, etc.) are readily available from a vendor of your choice and are not essential.

Please note: depending on what type of fluid you will use, the atomizers might clog, so make sure to get spares. Similarly, the surface plasma electrodes can get contaminated with minerals and chemicals in the water. Make sure to watch them and clean as necessary.

3D-printed parts list

Since the chamber needs to remain air- and water-tight, all of the 3D-printed parts need to be printed on an SLA printer.

Atomizer fluid chamber. Download the STL file. (Need 2)

Connector to the 50mm fan. Download the STL file. (Need 1)

L-shaped connector to Dernord™. Download the STL file. (Need 2)

Connector for the inside of the chamber. Download the STL file. (Need 2)

We regularly print batches of these parts, and we’re making them available in our Store.

Diagnostics

Here are some of the diagnostics we have performed on the OxyFog system. If you have additional diagnostics and analysis of this system available either online or in print, please email this information to greg@aaplasma.com.

Ozone measurements inside of the OxyFog system with and without the use of water nebulizers.

Optical emission measurements and photographs of plasma.

Case-use studies

As an educational tool

If you have completed a study and would like to feature it here, please email all the information to greg@aaplasma.com.